For patients with knee osteoarthritis, researchers have created a 3D-printed implant.

The customized osteotomy for knee alignment therapy has been created to protect the patient's current knee joint.

The method was created by University of Bath researchers to expedite and secure operations.

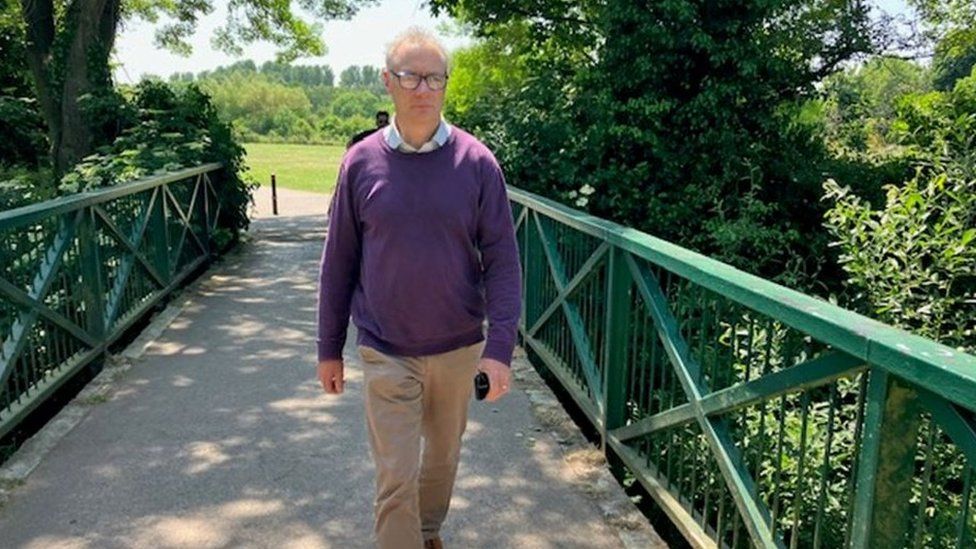

David Tarbet, 55, one of the first patients, called the procedure "remarkable" after receiving it.

Mr. Tarbet from Dartmoor, who participated in the high-tibial osteotomy (HTO) safety trial, said: "Although it was quite sore for a couple of months, I was able to get on an indoor bike quite quickly. ".

The 3D HTO plates are used to realign a patient's knee, improving their stability, comfort, and weight-bearing capacity over current generic plates.

Within six months, Mr. Tarbet claimed, he was able to complete a challenging bike ride, which was "fantastic.". ".

Doctors take an X-ray and a CT scan of the patient's shin bone to determine the extent of the necessary correction.

The 3D printer is then used to create a surgical guide stabilization plate.

This is then temporarily secured with pins to the patient's tibia, one of the two bones that make up the leg.

Following the removal of those pins, two screws are used to create a wedge in the bone that realigns it.

The stabilizing plate is then placed on top, making the surgical reality of the digital design possible.

In a computer-based trial using CT scan data from 28 patients, HTO plates have already undergone a virtual safety test. It resulted in the Medicines and Healthcare Products Regulatory Agency's approval.

Modeling the stresses that would be placed on the custom plates during the trial—the first of its kind to show the safety of an orthopaedic device—showed that they were equally safe as the accepted course of care.

A total knee replacement is not an easy option for patients between the ages of 40 and 60 because it won't last long enough, according to Prof. Andrew Toms, director of orthopaedics at the Royal Devon and Exeter Hospital, who is working with the university to develop the product.

"A knee has three 'car tyres,' an inner, an outer, and a kneecap," he said. All of those are replaced simultaneously with a traditional total knee replacement, just as you would with your car.

"When they are worn out, what we usually do is realign the knee in those younger patients to balance the knee out by relieving pressure from the worn car tyres and straightening the limb out.

"That is the main goal of this osteotomy technique. ".

The product was created at Bath University's Centre for Therapeutic Innovation by Prof. Richie Gill, who added: "The big difference is there isn't that guesswork which is happening at the time of surgery.

"I believe there is an increase in interest in this kind of joint-preserving surgery among surgeons.

"We hope to make it more widely available because you can do it earlier in the disease progression than you can with a knee replacement. ".

A trial comparing the traditional knee replacement with this method is currently recruiting 15 additional patients from south and west England, Cardiff, and Oxford after a preliminary safety trial with the five patients.