This factory in the southern Netherlands is owned by ASML, and the machines produced there are anything but ordinary. From the outside, it appears to be an ordinary corporate building with lots of glass and steel.

Because of how advanced and in-demand the technology is, ASML has emerged as the most valuable technology company in Europe.

What is produced there, then?

ASML creates and manufactures the equipment needed to create computer chips, but not just any old computer chips.

The most cutting-edge computer chips are produced by ASML machines, which are unique to their company in the world.

Because ASML effectively has a monopoly, the operation of its machines is protected by some of the most rigorous corporate security measures in the world.

Nevertheless, we were given a tour of its facility and taken through the fundamentals.

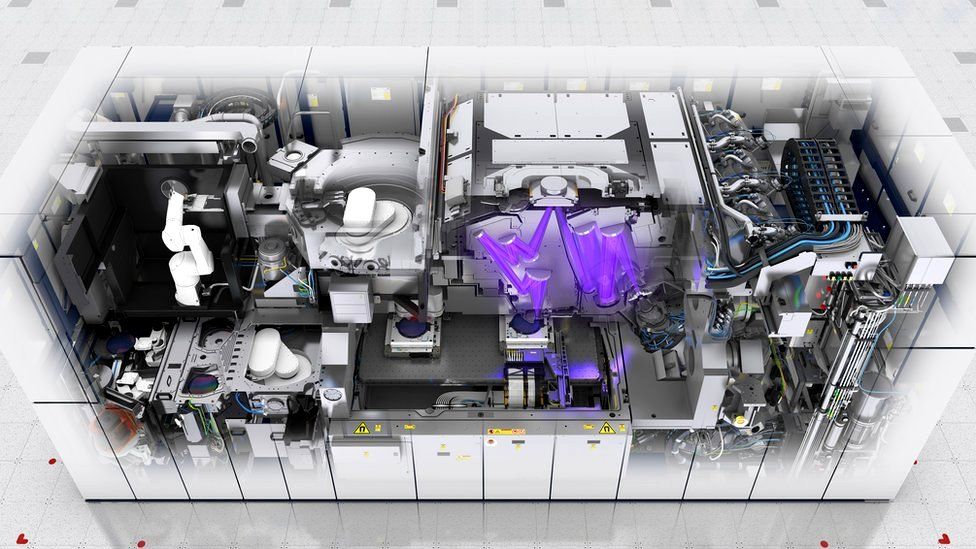

Microchips are created by layer-by-layer stacking intricate patterns of transistors, or tiny electrical switches, on a silicon wafer.

They are created by projecting light through a blueprint of the layout of those tiny switches in a process known as lithography.

A photosensitive silicon wafer is then etched with the pattern after the light has been focused and shrunk using sophisticated optics.

A silicon chip made from that pattern contains the circuitry that powers your computer, phone, or any other electrical device you care to name.

The ability of ASML's most cutting-edge machines to produce ultrafine light with a wavelength of just 13 nanometers allows them to operate at extremely small scales.

As an analogy, ASML's Sander Hofman says that drawing integrated circuitry lines is similar to using different-tipped pens. "Because of the small wavelength, that means that you basically are using a fine liner to draw these lines of integrated circuitry - instead of older generation machines which use maybe a marker pen," he says. ".

With the ability to etch the silicon with such tiny circuits, more components can be packed onto the silicon, increasing the processing power and memory of electronic devices while maintaining the same size.

Since even the smallest impurities, such as a stray skin particle, can cause the entire etching process of a chip to fail, the machines only operate in a vacuum.

When we visited the factory, Bram Matthijssen, an ASML technician, was assembling one of the most recent designs. One of the cleanest workplaces on earth is where Mr. Matthijssen works.

"There are times when we have to wear gloves over gloves to prevent leaving any fingerprints or introducing any additional dust into the machine.

"A solitary finger impression. can seriously harm the machine," the author claims.

The actual machines are massive and intricate. It can take a year to assemble and deliver a single extreme ultraviolet (EUV) machine.

In total, 400 machines were delivered by the company last year, but only 50 of the models with the highest specifications.

In addition to those sales, the company made 21 point 2 billion euros ($22 point 7 billion; £18 point 9 billion) last year from the management and upgrading of existing machines.

They have orders in the works worth twice that amount. The increase in sales translates into a workforce that has increased by a third in the past year.

The machines ASML creates take years, if not decades, to develop and perfect, according to Wayne Lam, a consultant with the technology research firm CCS Insights.

Since the beginning of the 2000s, ASML has been developing machines with the highest possible specifications, giving other businesses in the sector a lot of catching up to do.

"I'm certain there are rivals in the works. However, ASML doesn't have any real rivals in the near future, according to him.

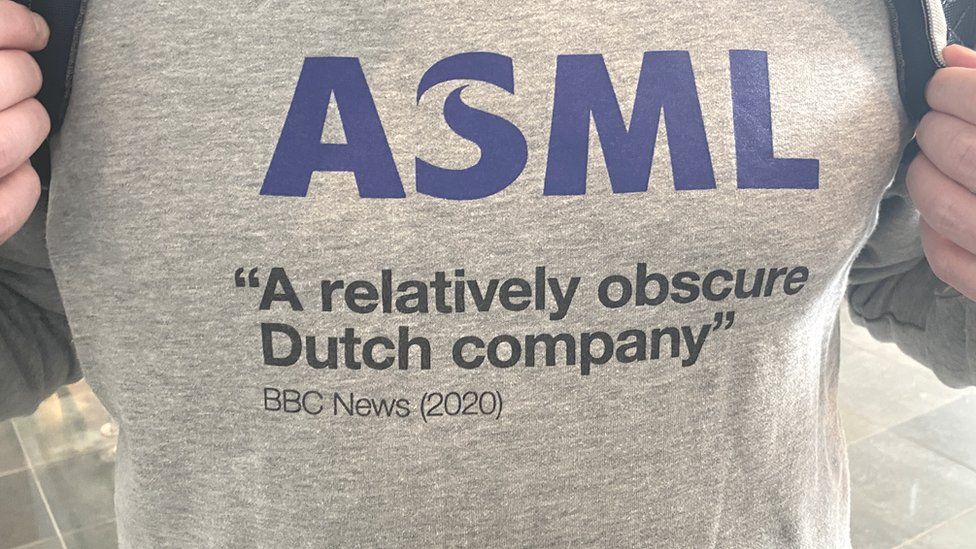

Not bad for a business that the BBC once called "relatively obscure," according to Mr. Hoffman, who has the phrase printed on a hoodie.

Being such a significant part of the global electronics industry presents challenges.

ASML is currently caught up in the conflict between the US and China.

In order to manufacture the most cutting-edge computer chips, China needs ASML equipment.

However, ASML has been effectively prevented by the US since 2019 from exporting those machines to China.

According to Joris Teer of The Hague Centre for Strategic Studies, the US is eager to stop China from catching up in chip technology.

"The US have changed their objectives from having a couple of generations of an advantage over their rivals to we must maintain as large a lead as possible - which can also mean you must put your rivals back as far as possible," he says.

additional business technology.

The details of a reported agreement between Dutch and US authorities regarding ASML exports have not been made public.

As a response to the news, ASML released a statement stating that any restrictions would require extensive work before legislation could be put into effect.

ASML CEO Peter Wennink does not anticipate that export restrictions will have a negative long-term impact on his company.

"Semiconductors will be produced in [South] Korea, the US, Europe, or Taiwan if China is unable to produce them. The world needs that capacity, so in the end we will ship those machines, he says.