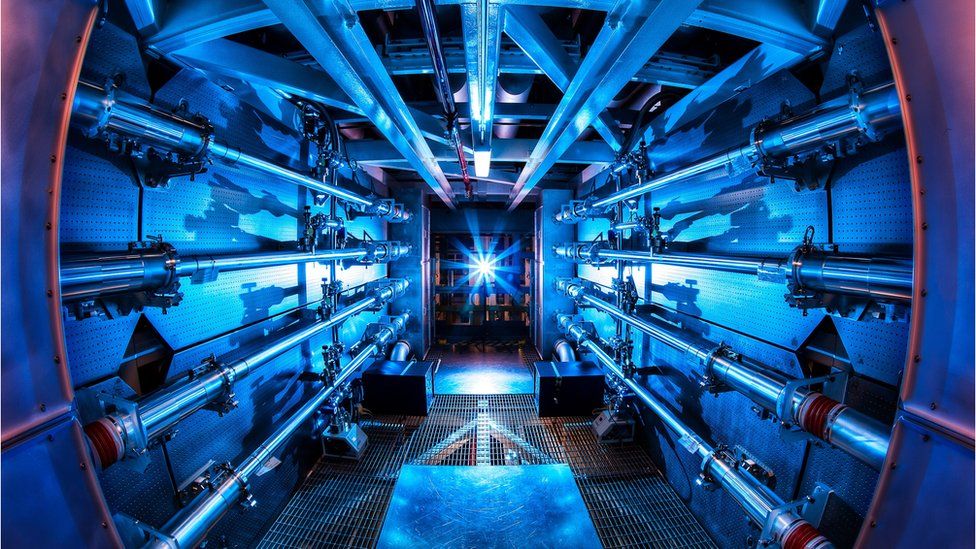

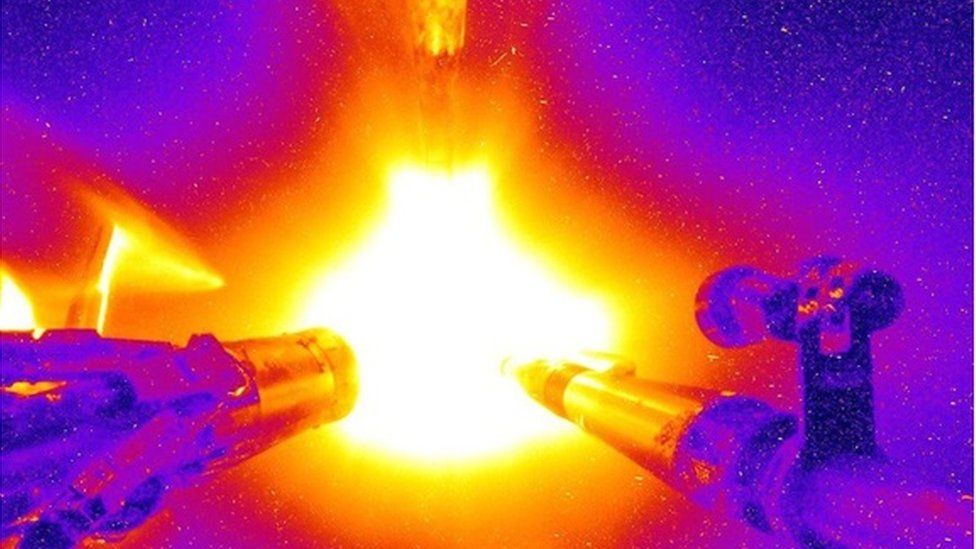

The National Ignition Facility in California's 192 beam laser was pointed at a cylinder containing a tiny diamond fuel capsule at 1:03 am on Monday, 5 December.

The sun's energy source, the fusion reaction, was sparked by that intense laser light burst, which also produced extremely high temperatures and pressures.

The National Ignition Facility (NIF), a division of Lawrence Livermore National Laboratory, had conducted similar experiments in the past, but this time the reaction's energy output exceeded the laser power used to initiate it.

The goal is to one day construct power plants that use a fusion reaction to produce a surplus of carbon-free electricity. Scientists have been working toward that goal for decades.

That is still some time away. In the interim, there is still much work to be done on the technology.

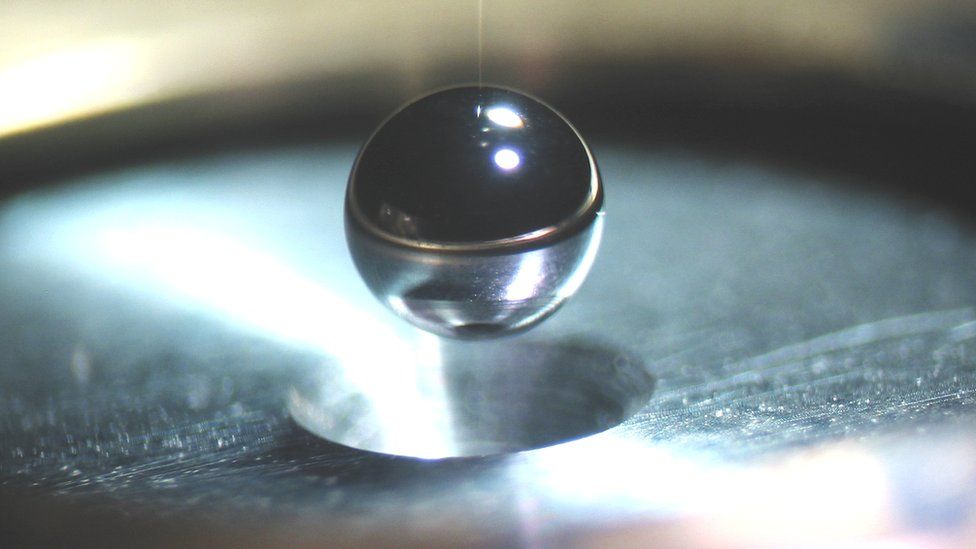

An important part of NIF is a peppercorn-sized synthetic diamond capsule that contains the fuel. To conduct a successful fusion experiment, that spherical capsule's characteristics are essential.

Any imperfections in the sphere could sabotage the reaction, so it must be flawlessly smooth and free of contaminants.

However, those intricately designed spheres are not produced in California. They are the end result of many years of labor by Diamond Materials, a business with headquarters in Freiburg, Germany.

In addition to Eckhard Wörner, Christoph Wild serves as managing director of Diamond Materials. He states that "the demands on the [spherical] capsules are very high.".

In order to minimize flaws like impurities, cavities, or uneven walls, we work closely with Lawrence Livermore. ".

Chemical vapour deposition is the method used by the 25-person team at Diamond Materials to create synthetic diamond.

Each batch of 20–40 capsules takes about two months to make, and they are painstakingly assembled by layering tiny diamond crystals around a silicon carbide core and then polishing repeatedly.

They found that even the most meticulous polishing was insufficient during the development process because the surface was pitted and uneven at the microscopic level.

Together with LLNL teams, they eventually learned how to glaze a polished capsule with a brand-new layer of diamond crystals to produce the desired clear mirror-like finish.

additional business technology.

When the diamond capsules are delivered to LLNL, the silicon core is taken out and the hollow sphere is filled with deuterium and tritium, two heavy forms of hydrogen that power the fusion reaction.

Mike Farrell, vice president of inertial fusion technology at General Atomics, which is LLNL's largest industrial partner, explains that the fuel pellet has a gold and depleted uranium cylinder surrounding it.

An aluminum cylinder serves as the capsule's third and last layer, and it is used to cool the interior before the reaction.

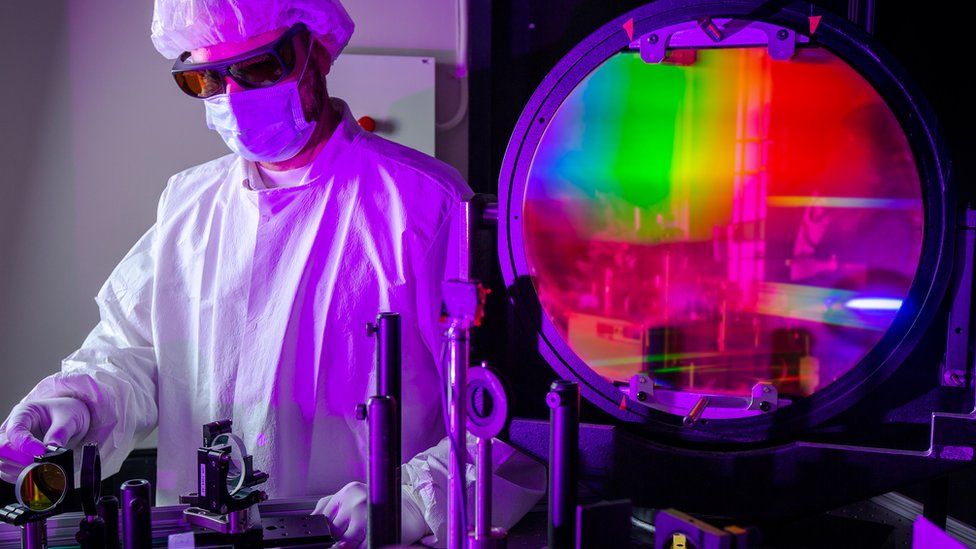

Optics—anything that supports the transmission, detection, or use of light—represents a further crucial area of technology for NIF.

As NIF uses a lot of that technology to power the most potent laser in the world, optical components are harmed each time the machine is turned on.

In order to perfect and provide replacement parts, as well as debris and blast shields, NIF has been working closely with optics manufacturers since the early 1970s, including Zygo Corporation and specialized glassmaker SCHOTT.

The goal for NIF and its partners going forward is to further advance technology in order to replicate and enhance the successful experiment from December.

Mike Farrell is hoping that this development will encourage support for more research. Scientific perception was altered by the experiment. Ignition was always considered to be almost unachievable and to only possibly occur in 40 years. The December outcome was startling. ".

Diamond Materials anticipates having more time to devote to research once it is back in Freiburg. According to Mr. Wild, "About 20% of our team is engaged in research, and both of us managing directors are also physicists.".

"Research at the level we produce requires a lot of resources, so production must not be neglected. As a result, the team will probably keep expanding. After all, the products of tomorrow are the result of today's research. ".

Teams from all over the world are frantically trying to construct a functional fusion power plant, employing a variety of strategies. However, it will take many years and numerous billion-dollar investments.

According to Mr. Farrell, the NIF milestone from last year will likely boost the industry: "Governmental and corporate funding may be simpler to come by now that ignition has been proven to be feasible. ".

This investment will be required to meet the significant engineering challenges involved in constructing a functioning power plant, not the least of which is finding materials that can withstand the high energy released during the fusion process.

However, Mr. Farrell is quick to point out how quickly advancements can pick up steam after the initial breakthrough.

"Engineers take the helm once first principles are demonstrated, as we just did, to determine how to accomplish that in a repeatable manner.

"Remember that the first flight made by the Wright brothers was in 1903, and the first supersonic flight was made in the 1950s. A lot can change in about 40 years.

. "